Hey there, folks! Bill here, and boy do I have some exciting news for you! Are you tired of using fragile glassware that shatters at the slightest pressure? Well, I have the perfect alternative for you – the one and only, enchanted acrylic material!

Now, I know what you might be thinking, “Acrylic? That sounds like a cheap knockoff of glass.”

But hear me out, my friends. This material is not only as transparent as glass, but it also outperforms glass when it comes to high-pressure situations. That’s right, no more worrying about your precious glassware breaking under the slightest bit of stress!

The enchanted acrylic material is like the superhero of the material world. It’s strong, durable, and can take on any challenge that comes its way. Plus, it looks just like glass, so you won’t even know the difference!

ent like glass, but when it comes to high-pressure conditions, it performs way better than glass.

Yes, I am talking about the enchanted acrylic material!

Gorilla Super Glue Gel is the Best Glue for Acrylic available on the Market today.

Now, I know what you’re thinking, “Gorillas and glue? What’s the deal?” but trust me, this glue is no monkey business.

When it comes to acrylic, this bad boy is the king of the hill. In just 10 seconds, it creates a bond so strong, it could rival a gorilla’s grip (see what I did there?). And let’s be real, who doesn’t want a glue that’s as tough as a 400-pound primate?

But listen, this glue isn’t for the faint of heart. You gotta be quick on the draw because it dries in just 10-30 seconds. So, make sure you know what you’re doing before you slap it on. But once it’s on, you can rest assured that your acrylic project is going nowhere.

Now, let’s talk about acrylic. This stuff is like the superhero of materials – flexible, durable, and can be used for just about anything. And with Gorilla Super Glue Gel, you can take your acrylic game to the next level. From home projects to DIY crafts, this glue is a game-changer.

However, there is a catch.

Unlike wood, acrylic is very hard to stick together. In fact, you cannot actually attach two pieces of Plexiglass over the glue. You need to chemically ‘weld’ those using special glues.

These specialized glues don’t just stick two surfaces together. Rather, they melt the connecting surfaces and bond them permanently.

It’s actually a great thing about Plexiglass. No other material is capable of truly fusing two separate pieces and look like a solid single piece like acrylic.

So, if you’re done cutting your colorful, attractive looking acrylic pieces, now it’s time to find the best glue for acrylic to bond them.

This is an important matter. You cannot just use superglue on these.

Good news is, we’re here to help you. So keep reading to know about Plexiglass glues, how to choose them and safely use them.

|

Acrylic glue |

Name |

Our Rating |

Price |

|---|---|---|---|

|

My Top Pick |

5 out of 5 |

||

No products found. |

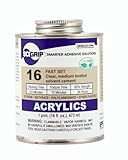

SCIGRIP 16 10315 Acrylic Cement |

5 out of 5 |

|

| Starbond EM-150 Medium Premium CA |

4.5 out of 5 |

||

| IPS Weld-On 3 Acrylic Plastic Cement |

4.5 out of 5 |

||

| Super Glue Plastic Fusion Epoxy Adhesive |

4 out of 5 |

||

| Sashco Big Stretch Acrylic Latex High-Performance Caulking Sealant |

4.5 out of 5 |

Table of Contents

My Favorites Top 10 Glues for Acrylic Tested

1. Gorilla Super Glue Gel

- GEL FORMULA: No run control gel formula that is great for use on vertical surfaces

- ANTI CLOG CAP: Helps keep the glue from drying out. It’s Gorilla tough use after use.

- IMPACT TOUGH: Specially formulated for increased impact resistance and strength

- FAST-SETTING: Dries in 10-45 seconds. No clamping required.

- VERSATILE: Bonds plastic, wood, metal, ceramic, rubber, leather, paper and more. Not recommended for use on polyethylene or polypropylene plastic or similar materials.

The name might sound funny, but Gorilla Super Glue Gel lives by its name.

Within 10 seconds of its application, this super gel will deliver a strong bonding unmatched to most glues out there. It usually takes 10-30 seconds to dry, so you need to be active and sure when you apply it.

According to polaroid fotobar research this glue has thicker than Gorillas popular super glue product.

It is made in a no-run formula. That means it won’t run over the vertical surfaces when you apply it. This feature makes the using astonishingly easy and controllable, something you crave while using glues.

The gorilla glue contains rubber particles in it which increases impact resistance. The quick setting time means you don’t need any clamping.

The application is fairly easy. Just open the cap and a narrow channel will allow you to pour the quantity you want.

Now, this super glue works great on a variety of surfaces. The specially formulated gel is compatible with rubber, plastic, metal, ceramic, paper even fabric.

In my research I found out that it is also the best glue for acrylic plastic.

Since we are discussing acrylic here, yes it is the Best Glue for Acrylic too. However, it won’t provide ‘gap fill’ which might be essential for effective bonding.

Another thing is when dried, this glue might leave white residue on the acrylic surface.

This might be demotivating for users using Plexiglass for public display purpose.

That being said, you need to weigh options between quick curing time and the cons and decide for yourself whether to use it for acrylic.

But for other materials, I’ll recommend this any day of the week.

Highlighted Features:

- This medium-bodied product comes with different packages.

- It bonds a wide variety of products from plastic to glass.

- Quick working and fixture time, 80% strength within 24 hours.

- The cement dries clear on surfaces, leaving zero residues.

- It has the ability to withstand humidity, temperature, and water.

2. SCIGRIP 16 10315 Acrylic Cement

No products found.

Imagine tripping glue at a wrong place and things suddenly getting messy.

Glues come in either liquid or gel form, also they dry within a short time. So there is little margin of error when you deal with adhesives.

But sometimes, manufacturers pay heed to the user demands and make things easy for them.Just like Starbond EM-150. This adhesive comes with extra micro tips and caps.

You can control the amount and place you apply glue on. Even if the liquid gets clogged, they provide an extra cap to deal with it.

EM-150 is something that you can say ‘general purpose’ adhesive. Being made of Cyanoacrylate, it has a surprising capacity to immediately bond surfaces.

Cyanoacrylate is widely known as super glue, so most of us are familiar with how fast they start working.

Since they dry within seconds, the adhesive needs to be free-flowing to quickly address bonding surfaces. Good news is, Starbond doesn’t fail to facilitate that.

It has a great viscosity of 150 cPs, which can be compared with the viscosity of motor oil. So it’s not too thin or too thick.

This one is a multipurpose glue. It can be applied to various surfaces like rubber, wood, stone, marble, granite, plastic, even acrylic.

The quantity might be too small to use on industrial Plexiglass applications. However, you should be able to use it for minor applications like acrylic nails.

This Cyanoacrylate glue comes in different bottle sizes. So if you’re looking for larger applications, you can save some bucks by purchasing bigger models.

Highlighted Features:

- Super strong adhesive, only a small amount is needed to form durable bonding.

- The gel is thick, doesn’t get messy and doesn’t run over vertical surfaces.

- It takes only 10-30 seconds to dry completely and achieve full strength.

- Made of rubber particles that hugely increase toughness and impact resistance.

- The gel is contained securely with an anti-clog cap.

3. Starbond EM-150 Medium Premium CA

We’re here with our first pick for Plexiglass adhesive.

But wait! This here isn’t your regular glue that just attaches two surfaces. This, sir, is an acrylic cement. Which means it efficiently welds acrylic sheets.

The SCIGRIP 16 10315 comes in a tube weighing only 5.6 ounces. That means you don’t have to worry about spilling adhesives due to a reckless movement.

Comprise of Methyl Acetate, Dichloromethane, Methyl Methacrylate Monomer, and Methyl Ethyl Ketone, this cement sets quickly on the surface.

The clear, thick cement is easy to apply, even if you are a complete noob. This high strength solvent immediately bonds two surfaces and leave no yellowish residue in the process.

We’re not finished yet! This one doesn’t only bonds Plexiglass surfaces, it also works equally well on PVC, polycarbonate, butyrate, ABS, and styrene.

If you have been tirelessly looking for a competent acrylic glue for fish tanks, here it is.However, you might need to use additional sealants to make the water tank completely leak-proof.

The chemicals used in this are pretty strong, so cautions are recommended.

However, this glue achieves 80% strength within the first 24 hours. Once completely dry, it’s as safe as the Plexiglass itself.

The cement starts drying within the first 5-6 minutes, so you don’t have to clamp the parts for long.This is a low VOC (volatile organic compounds) product. Which means the emission of harmful airborne particles is significantly low.

It stays clear and blends with the Plexiglass once it is dried.

Highlighted Features:

- General purpose repair glue containing cyanoacrylate, lab tested for optimal performance.

- Two applicator caps, one clog free stopper and several micro tips with the package.

- When kept in a cool environment, it stays in working condition for several years.

- High strength adhesive bonds surface within seconds, no clamping time needed.

- Can penetrate spaces up to 0.006 inches.

4. IPS Weld-On 3 Acrylic Plastic Cement

Acrylics, being a super strong and shock resistant material, needs special adhesive to bond.

You probably are looking for an adhesive that is exclusively made for Plexiglass. More importantly, can facilitate large scale applications.

The problem with normal glues is, they cannot actually ‘fuse’ surfaces, which is necessary when you work with Plexiglass. You’ll need weld on adhesives, a special glue that melts and rejoins the surfaces.

IPS Weld-on 3 cement is one such example. It softens the surface when applied, and then weld them together.

Within 24 hours of application, it gains 80% strength. On top of that, it is made for DIY and industrial applications.

That’s not just a hollow claim. The product comes with a 4-ounce can. But it can be messy when you try to use the glue directly from the can.

That’s why the manufacturers provided with applicator bottle with a needle. Now, you can reach difficult angles without spilling glues.

The liquid is water thin. But thin it comes short when delivering. The glue has a working time of 1 minute and a fixture time of 2 minutes.

You set up the parts, apply glue and wait for a little. Bam! The quick setting glue is on work.

Apart from acrylic, this glue works wonder on butyrate, styrene, and polycarbonates.

The cement usually doesn’t leave residue when dried, unless there’s high humidity.

So you can apply it on fish tanks, display cases and headlights. Being a non-flammable product, it does improve your safety conditions.

Highlighted Features:

- A water thin cement with clear aesthetics for acrylic surfaces.

- Quick setting time, starts bonding within minutes after application.

- Apart from Plexiglass, bonds well with other polycarbonates.

- Comes with an applicator bottle and needle for ease of use.

- Can be used for personal, DIY and industrial purposes.

5. Super Glue Plastic Fusion Epoxy Adhesive

Sometimes apparently ordinary things can surprise you.

Take Super Glue Plastic Fusion for example. This product cost so low that you might think it’ll probably fail to deliver. And to your surprise, it will do the opposite.

Why? One word, epoxy. Epoxies are known to be strong adhesives. This one here lives up to its reputation by delivering a holding power of 4000 psi.

It starts working within 8 minutes of application. It gets strengthened over time and reaches optimal strength within 24 hours.

The bottle doesn’t look like your regular super glue bottle. It’s something unique, and it’s designed that way for a good reason.

It comes in a bottle with 2 heads, one dispenses resin and another one dispenses hardener.

Together, they work as a strong adhesive and bonds a variety of surfaces including nylon, PVC, ABS, plastic, metal, and concrete.

It works well for temperature between -40 to 250 degrees Fahrenheit. Unless you live at the center of the earth, you have nothing to worry about.

When you apply this glue, make sure both surfaces are clean. Also, remove excess glue immediately after use because it sets down quickly.

The glue isn’t clear, rather it is yellowish. When it gets dried on the surface, it will leave a slightly yellowish residue.

If you have kids, keeping this around might come handy. I mean you’ll stumble upon a lot of broken toys and with the help of this glue, you can get them ready for further tortures.

Highlighted Features:

- Plastic fusion adhesive with OZ epoxy adhesive.

- High-stress endurance can hold up to 4000 pounds per square inch.

- Starts setting with 10 minutes of application, 100% strength within 24 hours.

- Resin and hardener work together to deliver high bonding strength.

- Works well with plastic-based acrylic, metal, concrete, and PVC.

6. Sashco Big Stretch Acrylic Latex High-Performance Caulking Sealant

Talk about versatility, uniqueness, and performance, all within one product!

Sashco Big Stretch Sealant doesn’t just work well on your regular household fittings like bathroom tiles, it also bonds surfaces like vinyl and acrylic.

This is a water-based elastomeric product. The inner materials are caulk like gel materials, which are highly heat resistant.

This amazing sealant can endure temperature ranging -30 to 250 degrees Fahrenheit.

The caulk has a smooth texture, it provides a great ‘fill gap’ and can be applied with nominal efforts. It can fill gaps of 2 inches with ease, while most superglues don’t even cover half inches.

If you stretch it, the material can extend up to 5 times the original size. Not only stretching, but you can also use it how you wish, twist, compress, bend and stick it to surfaces.

You’ll be amazed by hearing how much surfaces it works on. Acrylic sheet, ABS, brass, steel, vinyl, brick, stone, fiberglass, asphalt, tiles, drywall, fiber cement, I can go on and on.

This superior elasticity and strong adhesion make it extremely useful for household applications like interior walls, doors, vents, sliding, crown molding, etc.

If you are a lover of colors, this product will serve you well with its 12 color variations.

You can do additional painting matching your surface within 4-48 hours of application, depending on whether you’re using exterior or interior latex paints. For acrylic, you’ll probably like to use the white color.

The product comes in a bottle of 10.5 ounces. This economical pack can cover 26 lineal-feet with the materials within.

If you’re looking for the best acrylic adhesive that also works as a sealant, you can try this one.

Highlighted Features:

- Water-based, heat resistant sealer with more power than silicone caulk.

- Can be applied and used easily thanks to the smooth texture.

- Flexible caulk, Can be twisted and stretched as you wish and provide a good gap fill.

- The product comes with a variety of color options.

- Adheres well to a wide range of surfaces including.

For those of you who need acrylic for cement, here are a few of my recommendations when working with cement.

With my research I found out that these acrylics are the best one to glue to a cement rapidly and very stable.

SCIGRIP 16 Acrylic Cement

We’re here with yet another Scigrip product, but this one is thicker.

The SCIGRIP 16 is a weld on 16 adhesive, which is apparent from the name. Unlike the #3 or #4, this way is thicker in nature, almost thick like actual cement.

But would it hinder your application? No. If you need this cement to be more liquid, you can add additional acetone and it’ll be ready for use. The thickness helps when you have larger gaps to fill.

The bottle comes in a convenient 1 pint (16-ounce quantity). Judging from the quantity, you can use it for large scale projects.

The substances used in this adhesive are strong, so strong that they might harm you if not used in a controlled environment.

However, they are the substances that aid in the high strength of this cement. It sets up pretty quickly, typically within 5-6 minutes of application.

Within 10 minutes time, you’ll be able to move the structure without risking further weakening. The adhesive achieves 80% strength with 24 hours from its application.

Not only Plexiglass, but Scigrip 16 also works equally well with other materials. You can use it on PVC, styrene, butyrate, ABS, polycarbonate, etc. These type of cement is the best glue for acrylic, yielding a far better result than super glues and epoxies.

The manufacturers claim the product has low VOC, meaning less harmful chemicals.

But judging from the components, you better not vape or touch the product. That is just for safety reason. As for competence, it will satisfy you beyond expectations.

Highlighted Features:

- High strength, quick-setting adhesive that works well on Plexiglass.

- Working time and fixture time is 5-6 minutes and 10 minutes.

- It comes with a large quantity, but the price is easily affordable.

- Works on different surfaces apart from plastic and acrylic.

- Can be used for display cases, aquariums, and fish tanks as glue and sealant

Weldon #4 with Applicator Bottle

We’ve discussed weld on #3 and #16 adhesives, so #4 deserves the next place.

This is an amazing adhesive. It isn’t thin like #3, but not super thick like #16 either. This glue strikes a nice balance between the two.

The product under my test is Weldon #4 with Applicator Bottle. The glue does come in a can of 4 ounces.

However, you definitely aren’t going to apply directly from the can. Thus the provided applicator bottle will serve you with precision.

This is a blush resistant cement. Don’t worry, it might not blush like your loved one, but you probably won’t want your acrylic surfaces blushing (leaving white residue).

With 2 years of shelf life, you don’t need to worry about the product expiring anytime soon.

Upon application, the glue quickly set itself in within 1-2 minutes. With a fixture time of 3 minutes, you definitely won’t have to waste time sticking around the structure.

The glue gets stronger over time and with 24-36 minutes, it’ll reach its maximum strength.

This product can be used for various acrylic uses such as display case. Since it leaves no residue, you can use it to assemble medical equipment.

Using capillary method, this product was applied in many solvent fused structures and provided satisfactory performances.

If you want faster setting time, a weld on 3 is recommended. However, if you want a slightly thicker and stronger performance, go for this one.

Highlighted Features:

- This cement fuses acrylic surfaces and bonds them strongly and permanently.

- Sets within 1-2 minute and starts getting fixed within 3 minutes.

- Blush resistant usually doesn’t leave white residue when dried.

- Can be used to assemble display cases and medical equipment.

- Applicator bottle with cap and needle is provided for ease of use.

Scigrip 4 10308, Weldon 4 Acrylic Solvent Cement

No products found.

An adhesive isn’t something you can mess with.

I mean, you can get all playful and untidy when you work with paints. Often, any mistake you make is revocable. You can even muddle your clothes and skin in the process!

But, not with strong adhesives. Any wrong application and you’ll probably have to toss the joining parts.

Getting those adhesives in touch of your skin is out of the question. That’s why you should always look for convenient application methods.

Good news is, products like Scigrip 4 10308 makes our life way easier. This one comes with an applicator bottle and two needles, one of which is 21 gauges.

With the help of these apparatuses, you can reach difficult angles and have control over your application. No spilled glues and irritated skin will bring the nightmare to your DIY projects.

Just like the previous product I tested, this one is also blush resistant. It will work with thermoplastics, polycarbonate, and polystyrene. However, this one doesn’t feature well on cross-linked acrylics.

This weld on 4 glue is water thin, so you can apply it directly on the surfaces. Unlike many other adhesives, this one is non-flammable, which gives a little bit of relief on the users’ part.

Since it leaves no residue, it is usable display cases, ships, automobiles, medical equipment assembly, etc.

Highlighted Features:

- Moderately fast setting.

- glue with 1-2 minutes working time and 3 minutes fixture time.

- Doesn’t leave white residue on surfaces when dried.

- Works well with thermoplastics and polycarbonates, even metal.

- The 4-ounce bottle comes with 2 long needles for precise application.

Aron Alpha Type 232 (300 CPS) Fast Set Instant Adhesive

When we talk about the best acrylic glue, the one probably pops to mind is structural acrylic adhesive.

That’s actually understandable. No other glues work better than these adhesives. They practically melt and then weld the joining surfaces. Once joined, you won’t even be able to tell these two surfaces were separated.

Usually, cyanoacrylate and epoxies fall short in performance when it comes to exclusive use on Plexiglass. However, there are some bright exceptions. Adhesives that work as strong as acrylic cement.

The Aron Alpha Type 232 is one such adhesive. This one contains Ethyl 2 cyanoacrylate, which instantly bonds surfaces, even acrylics. The glue is even engineered to work on hard-to-bond situations.

This one might not provide huge gap fills, 0.006 to be precise. However, it delivers quick drying.

Depending on the surface it takes as low as 3 seconds (PVC, neoprene, ABS), 5 seconds (acrylic plastic) to 10 seconds (steel). The adhesive takes 24 hours to fully strengthen, although it fixes way before that time.

The glue can continue performing in -65°F – 180°F temperature range. The viscosity is 300 CPS, which works well on porous materials.

It works on a wide range of surfaces including plastic, rubber, and metal. Also, the viscosity allows it to work on surfaces like wood and leather.

Cyanoacrylate is known for its clear appearance and high tensile strength, this one is no exception. It shows high tension endurance on surfaces like steel (2840 psi), stainless steel (2560 psi), ABS (700 psi).

Highlighted Features:

- Ethyl 2 cyanoacrylate adhesive with a super-fast setting and curing time.

- The medium viscosity makes it apt for porous materials.

- Comes with applicator channel and anti-clog cap.

- The glue starts drying and curing within 3-10 seconds of application.

- Specially engineered to work on hard-to-bond surfaces.

How To Choose The Best Glue For Acrylic?

1. Types Of Acrylic Glue (Material)

Glues can be a tricky thing!

One glue working exceptionally well for one material might not even stick to another material. For example, the universally known super glue works wonder on wood, leather, ceramic and even glass.

However, they might not work well for acrylic. In fact, they leave a visible white mark when they dry on Plexiglass surfaces.

Top glues for Plexiglass

Considering two acrylic surface needs to be fused instead of a mere attachment, you need special kind of glue materials for the job.

Here are several competent types of acrylic glue for Plexiglass.

A. Cyanoacrylates

These glues are suitable for high-speed production lines. That’s because they have a very short curing time. However, the rapid curing time might pose challenges for slow or unsure users.

The glue can work on their own, without the help of any mixing or curing material. They can fill a maximum gap of 0.5 mm, which might prove insufficient for many applications.

Like we said above, cyanoacrylates, also known as super glue leave residue on Plexiglass surface. When the user tries to wipe the excess glues adjacent to the joint, the adhesives might fog the surface.

There is a solution though, if you use alkoxy-ethyl cyanoacrylates instead of regular ethyl cyanoacrylates, the noticeable powdery residue will be lesser.

B. Epoxy Adhesives

There are two types of epoxy glue for acrylic plastic. The single component epoxies are usually avoided. That’s because the high temperature needed to cure them eventually damages the acrylic.

The two-component epoxies are widely used on acrylic. They have a longer cure time and can facilitate a larger gap fills. These two features make it suitable for various uses.

They have quite some grades which work just fine. However, ET500 and ET515 are preferred over others because they are clear grade.

Over application on thick surfaces, these glues might leave a slight yellowish effect.

C. UV Curable Adhesives

Usually, commercial acrylics are UV stabilized. That means they don’t get destroyed by the sunlight, and block some or all of the UV rays received from the sun.

Applications, where sunlight is a real factor, needs using of these acrylics. On the other hand, applications which don’t include sunlight, like medical equipment can use non-UV resistant acrylics.

If you’re using the former one, you can use UV curable adhesive. They, when exposed to UV rays, cure within 3-15 seconds. This allows you to use the UV rays and control the process on your own speed.

They are great acrylic glue for aquariums because they offer very strong liquid surface bonding, good gap fill, controllable and fast curing speed. On top of that, they don’t leave any white or yellow residue on the clear surface.

D. Structural Acrylic Adhesives

They are comparatively new on the line of acrylic adhesives. However, they provide a bond unmatched to any other glue. Here, you use MMA structural acrylic adhesives to bond two Plexiglass surfaces.

As a result, you’ll get a crystal clear aesthetic appearance, free from any yellow/whitish mark.

But the problem is, they are flammable and emit a strong odor. Often they are avoided for these reasons. However, there are hardened and low odor acrylic adhesives which reduce these factors.

2. The Cure Time

This is the time the adhesive takes before it gets dried. The time varies for different glues. It can be from several minutes to a day.

Some glues provide instant strength, while some get stronger as time passes.

If you are in a hurry, you can use glues with shorter curing time. Cyanoacrylates are one of these glues. However, the bond between surfaces might be weaker than you thought.

If you want permanent and strong bonding, say for display cases, aquarium or auto parts, then you need to turn to stronger glues with longer curing time.

They might not deliver instant curing, but they will get super strengthened after a day or two.

3. The Clamping Time

This one is different than curing time. This is the time you need to hold the parts together as the glue is drying.

It might take one day to cure, but the parts can stand on their own within the clamping time.

Now, if you’re working on large projects, longer clamping time will take up much of your schedule.

So you need to strike a balance between clamping time and curing time. You can choose glues that have 30 seconds to 1 minute clamping time.

4. Residue On Surface

This is an important buying decision for acrylic users. Colored and transparent acrylic both are available on the market.

However, Plexiglass is often used for its clearness while delivering great strength. Some of the uses include lenses, screens, roof windows, fish ranks, headlights, sales display.

It’s clear from the uses that any residue on the surface will not only hinder the objective but also will be aesthetically unpleasing.

The best adhesive for acrylic will be the product that doesn’t leave such marks.

Some glues leave white or yellow residue when they dry. If you are using for an application that includes public appearance, you better stay away from these glues.

How to Use an Acrylic Glue?

Regardless of what type of glue you are using, there are several steps you should complete while applying the adhesive.

Since these products have a quick curing time, you need to be prepared and create the best working condition for them. The steps are-

1. Clean The Surface:

If there is dirt, grime or residue on the surfaces, they won’t stick well to each other. Make sure you thoroughly wipe and clean both surfaces that are needed to be bonded.

2. Sand The Surface:

That’s because smoother surface works better as host for glues than rougher surfaces.

The reason is smoother outsides avail more contact surface with the glue, allowing for better bonding. Clean the surface when you’re done.

3. Test Feasibility:

Before starting any project, it’s essential to test the feasibility of the glue. Not all glues work well with all surfaces.

Some perform better than others of a given surface. Check beforehand which glue works well, see how it fills the gap and the clamping time needed.

4. Clamp Properly:

This is especially important because if you don’t hold the parts and give the adhesive necessary time to work, then the bonding will be weak. Make sure you press one surface firmly against the other surface.

The clamping time is generally available on the bottle label or manual.

Safety Issues That You Need To Consider When You Use Acrylic Glue

Glues are extremely tacky materials. Apart from wrong applications, one might physically experience the wrath of tackiness if not careful. Check out the safety issues you need to be careful about-

1. Best Acrylic glue Physical Hazards

Some glues are flammable, while others are known for their extreme stickiness. If you’re not careful, flammable adhesives might come in contact with fire and spread rapidly.

Also, glues like cyanoacrylates will instantly attach to your fingers once you touch them. That’s why we commend wearing proper eyeglasses and gloves during application.

2. Toxicity Hazards for Best Acrylic glue

Glues are made of strong chemical components. Some of them might cause skin allergies, irritations, and troubled feeling when you come in touch with them.

Also, some adhesives are so strong that might your respiratory system.

To avoid this, we suggest you know your glues. Read the user manual carefully before using the glue. Take necessary precautions as per the instruction manual. Use face masks and gowns if necessary.

3. Best Acrylic glue General Safety Measures

The workstation where workers deal with glues is a sensitive area. The air should always be circulated to clear out airborne pollutants.

The workplace should be equipped with air circulation fans and ventilators.

The area should be prohibited from any food or drink. The user or worker should not eat or drink in the working area. Also, the user needs to wash the exposed body area while entering or leaving the working zone.

Make sure your workplace temperature is between 70 and 75 Fahrenheit for the best result. Also, a place with relatively low humidity will improve working condition a lot.

4. Avoiding Financial Loss – Best Acrylic glue

This one is not associated with physical safety per se, rather with financial safety. Since glues take only several seconds to minutes to bond surfaces, you need to be careful how you’re using them.

You need to draw an outline of what you want to accomplish beforehand. Plexiglass bonds over fusion with each other.

So make sure you’re joining the right parts. Join wrong parts, and you might have to toss both parts altogether.

FAQs

Q1. What Is Acrylic Glue?

Answer: Acrylic glue is an adhesive that is based on resin. Acrylic glues are often a kind of polymer rather than usual glues.

It is made of acrylic or methacrylic polymers. Often resistant to sunlight, these glues are humidity/ water resistant.

Q2. How Do You Clean Acrylic Sheet Before Gluing?

Answer: If the sheet looks dirty and dusty, use water and mild soap mixture to clean them.

Use a soft cleaning cloth to wipe the surface. Don’t use ammonia-based cleaner because it’ll eat into the sheet.

Q3. Can You Remove Solvent Cement From Acrylic Sheet?

Answer: Once the cement is applied, the surfaces are fused permanently. Thus, you cannot just remove the cement.

Any excess cement gets evaporated and leaves a slight residue. You can buff the surface to smoothen it.

Q4. How To Remove Acrylic Glue?

Answer: You cannot remove acrylic glue without damaging the Plexiglass sheet itself.

The glue melts the two connecting surfaces and forms a permanent bond. As for excess glue outside of the joint, you can do sanding and buffing.

Q5. How To Remove Nail Glue From Skin?

Nail glues are often made of cyanoacrylate or other glues used for Plexiglass. Besides, you might accidentally touch Plexiglass glue while applying them to the surface.

If that happens, do not harshly rub the skin. Soak it into hot soapy water for 15 minutes. Use a toothbrush to gently scrub the skin area, don’t forcefully rub it. Apply acetone-based nail polish remover.

Soak a cotton ball or pad and hold it on the affected area for 10 minutes. Gently brush off the glue using a toothbrush again. Rub oil or petroleum jelly gently on the affected skin to remove glue residue.

Q6. What To Do If Acrylic Glue Come In contact To My Skin?

Answer: If the glue comes in contact to your thicker skins, like fingers or hands, then follow the steps we discussed in the previous question.

If the glue finds its way to your sensitive skins, i.e. lips, eyelids, face skin, do not apply acetone on them. Soak them with warm water and see a doctor immediately.

Q7. What Glue Is Used For Acrylic Nails?

Answer: One of the common uses of acrylic is fake fingernails. Thus, you need specialized glues to attach them.

Usually, cyanoacrylate aka the super glue is used to attach acrylic nails. However, the ones used for nails isn’t necessarily the same as household ones, they differ in viscosity.

Other acrylic adhesives like epoxy, polyurethane glues, and silicone based adhesives are suitable for DIY or construction projects rather than artificial nail uses.

Q8. How To Bond Acrylic To Wood?

Answer: To attach wood and Plexiglass together, you’ll need two component epoxy.

Example of such epoxy glue is 3M Scotch-Weld DP100. Make sure you work quickly as it tends to dry quickly.

Q9. How To Bond Acrylic To Glass?

Answer: Acrylic is far lighter and stronger. However, it is possible to bond acrylic to glass.

Clean both surfaces with isopropyl alcohol. Sand the acrylic surface evenly so that it will be as flat as possible. Use epoxy glue to bond the surfaces together.

Q10. How To Bond Acrylic Together?

Answer: You can use acrylic cement. These are glues but slightly different from regular glues. It is a solvent that welds of fuses two acrylic surfaces together.

Sand the surfaces beforehand to increase surface contact between the two. Make sure the pieces don’t have any gaps between them.

Hold or clamp the pieces firmly in the desired position to let them attach together.

Be cautious when you use cement on larger projects. Use of excess glue might damage the acrylic and the pieces might be too ruined for further use.

Q11. Does super glue work on acrylic?

Yes super glue works on acrylics, it sticks to it firmly and create a strong bond. Gorilla Super Glue is the one most recommended for the job.

As in addition to acrylic it also works on other different surfaces such as metal and plastic.

La Finale

Gluing acrylic might sound like a big challenge to some, while it’s actually as easy as gluing woods.

I mean, yes, the adhesives are stronger, so strong that they can fuse acrylic. They have a quick curing time. But that’s won’t pose any problem if you know what you’re doing.

With a proper plan, the right glue and a little bit of patience, you can achieve unbelievable feats with Plexiglass.

The main mistake people do is choosing the wrong glue for the wrong job.

Depending on the job, the best glue for acrylic might be different for different people.

This is where this article can help you. We have discussed different glue types with their advantages and disadvantages.